Some form of traditional supply chain planning exists in all organizations. In many cases, however, these processes focus only on the short-term execution horizon. ChainSequence experts transcend typical Sales and Operations Planning (S&OP) or Integrated Business Planning (IBP) programs with data-driven analytics and forecasting tools that enable your business to achieve a more beneficial, long-term view.

ChainSequence’s S&OP planning services were meticulously developed to work in concert with traditional supply chain planning practices, allowing your business to gain evidence-based insights and measure progress within a well-structured, inclusive program. With our expertise, gain the capability to maintain and drive focus, collaboration, alignment and synchronization among all of your business units. We can help your enterprise keep the emphasis exactly where it should be—on the strategic horizon where proactive change positively impacts execution.

How ChainSequence Can help your organization:

- Your company has no formal S&OP process

The ChainSequence S&OP program is a great way to get alignment across your team, establish a common understanding of the process, and begin to develop an approach to an S&OP process that is right for your organization.

- Your company’s process is not meeting expectations

Your organization has an S&OP process, but it’s not effectively achieving your longer-term goals and financial objectives. How can ChainSequence help us?

ChainSequence starts with an assessment of your current S&OP and supply chain planning processes. Although all companies face similar challenges, no two are exactly alike. We’ll help you address your unique differences with practical solutions to improve your S&OP planning capabilities. We focus on identifying your key challenges to determine and recommend the most appropriate S&OP and Supply Chain Planning solutions.

Successful S&OP programs ultimately depend on three factors: 1) all impacted business organizations are fully engaged; 2) the business has the tools in place to adhere to the defined cadence of each monthly cycle; and 3) every executive manager recognizes the value of such a process, actively participates, and has the appropriate information to make informed decisions.

The assessment identifies the underlying root cause of issues and recommends solutions to address and resolve each issue. The ineffectiveness of the S&OP program may also be the result of fundamental supply chain planning processes and principals the don’t support the S&OP process.

An S&OP program may also be ineffective as a result of fundamental supply chain planning processes and principles that can sabotage your S&OP program. A thorough review of your current supply chain planning processes will ensure a sound foundation to support your S&OP process moving forward. Omitting this step can best be described as a building a house on a foundation of sand—while the house may look supported at first, it will eventually, and inevitably, crumble.

Our ultimate goal is to identify a roadmap of incremental solutions that can quickly improve the effectiveness of the S&OP process over time.

- Your company needs S&OP training

Because every business is different, our S&OP facilitation teams take the time to learn more about your business, your mission and goals. We work with you to better understand and develop a clear roadmap that guides your business in developing a new process—or creating better standard practices—while also promoting discipline and adherence to those new or improved processes.

Our goal is to help you jumpstart your Sales and Operations Planning initiatives, by providing the necessary education, examples, and best-in-class standardized processes.

| ✢ | Introductions, Objectives, Agenda | |

| ✢ | What is S&OP; why do you need it | |

| ✢ | S&OP Guiding Principles | |

| ✢ | Primary steps of an S&OP process | |

| ✢ | Defining organization involvement | |

| ✢ | Defining the calendar and cadence | |

| ✢ | Need for data integrity | |

| ✢ | Reporting and dashboards |

The journey of a thousand miles begins with one step

Lao Tzu

While the concept of S&OP planning is certainly not new, developing an effective S&OP process takes time. ChainSequence also understands that S&OP Planning depends on periodic reviews and updates which can be critical to the success of your organization’s ability to achieve its long-term strategic goals. Our team conducts the crucial due diligence required to ensure that your S&OP planning efforts enable effective supply chain management that is appropriate for your unique organization. Whether you’re looking to implement a new process, or improve a program already in place, the ChainSequence team has the experience and expertise to help your business develop and navigate the best path toward long-term growth and success.

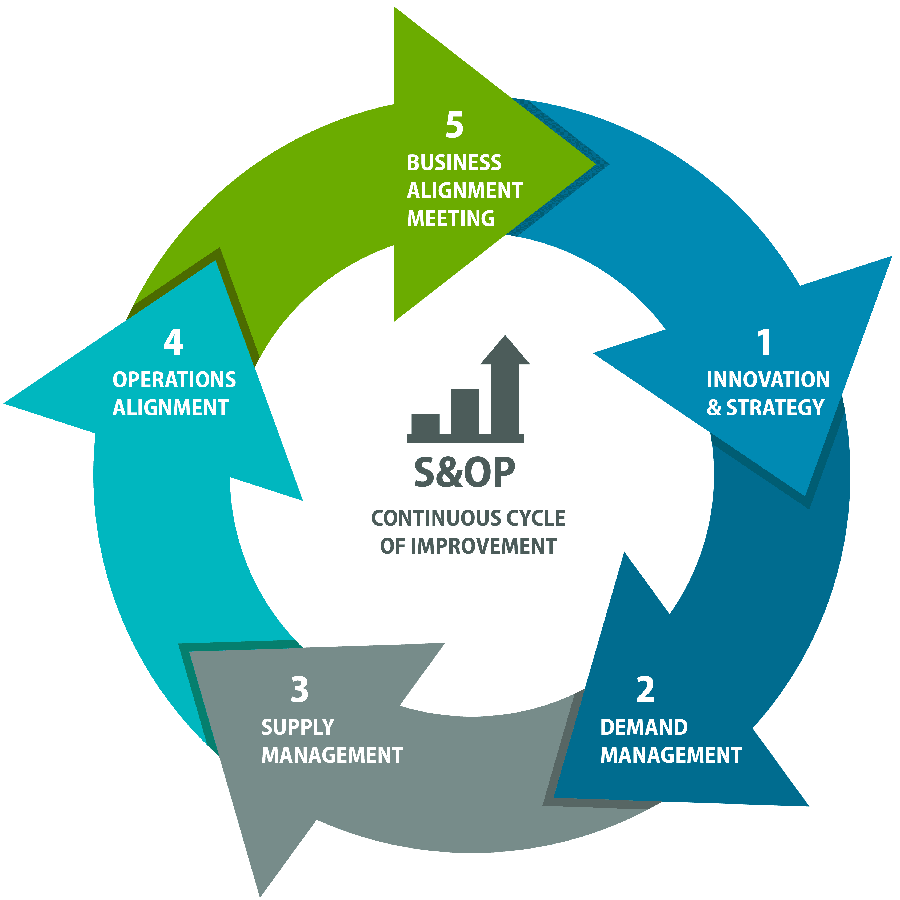

The Five-Step S&OP Process:

- Step 1

- Step 2

- Step 3

- Step 4

- Step 5

- Key Metrics

- The Benefits

1 — Innovation & Strategy

Review and discuss product portfolio performance and roadmap update demand shaping input from Product Marketing / Product Management and Marketing. KPIs review should include discussion on opportunities for improvement.

Step Result: Product roadmap updates, Product portfolio adjustments, and SKU rationalization actions for improved demand and supply shaping

2 — Demand Management

Develop a single, unconstrained view of the forecast utilizing input from a variety of sources, including AI/system-generated demand plans and market and customer trends and intelligence. Prior to this meeting, there may be multiple meetings grouped by product lines or sales channel to review opportunities and risks that may shape the ultimate consensus demand plan.

Step Result: 18+ month unconstrained consensus demand plan

3 — Supply Management

Review the current demand plan, evaluating risks and assumptions compared to target inventory levels, and generate a supply response plan. Discuss supply scenarios to address constraints, procurement or logistics issues. Balance supply with demand and develop a preliminary constrained demand plan. Review longer-term production capacity for capital planning and investment. Step Result:Supply chain network gap-closing scenarios to unconstrained demand plan and preliminary constrained demand plan4 — Operations Alignment

Review proposed operating plan compared to financial plans based on preliminary constrained demand plan. Focus on revenue shortfalls, production constraints, and excess inventory. Discuss scenarios and trade-offs to present a recommended operating plan to the Executive Management Team for final approval. Step Result:Proposed operating plan with demand and gap closing scenario actions5 — Business Alignment Meeting

Focused Executive review to discuss and approve a single operating plan based upon recommendations. If necessary, approve actions to close gaps to the financial plan (budget). Review business performance and assign actions to address issues and improve performance. Step Result:Final constrained operating plan with actions to be taken in subsequent S&OP cyclesThe Benefits of S&OP

Focused Executive review to discuss and approve a single operating plan based upon recommendations. If necessary, approve actions to close gaps to the financial plan (budget). Review business performance and assign actions to address issues and improve performance.

Overall Result: Final constrained operating plan with actions to be taken in subsequent S&OP cycles

Customer Service/Satisfaction

Customer Service/Satisfaction